不锈钢矩管价格表

您好,很高兴能为您一下不锈钢矩管价格/a的相关问题。我希望我的回答能够给您带来一些启示和帮助。

文章目录列表:

1.377*5/6/7/8/9/10.无缝钢管规格表,无缝钢管米重价格相差多少2.304不锈钢装饰管价格以以及

3.201不锈钢j1/j4/L1/L4/D7/D9,还有光洁度都是什么意思?我想做不锈钢装饰管,需用哪种?价格哪种低?

4.华为手机背面有AI CAMERA f/1.8+f/1.8是哪款手机?售价多少?

5.有人能告诉我钼精矿买卖的价格单位:元/品位是什么意思么?它的每吨交易价格要怎么换算?

377*5/6/7/8/9/10.无缝钢管规格表,无缝钢管米重价格相差多少

一、无缝钢管重量计算公式:[(外径-壁厚)*壁厚]*0.02466 = kg/米(每米的重量)

377*5=45.86公斤/每米

377*6=54.89公斤/每米

377*7=63.86公斤/每米

377*8=72.79公斤/每米

377*9=81.67公斤/每米

377*10=90.5公斤/每米

二、无缝钢管具有中空截面,大量用作输送流体的管道,如输送石油、天然气、煤气、水以及某些固体物料的管道等。钢管与圆钢等实心钢材相比,在抗弯抗扭强度相重量较轻,是一种经济截面钢材,广泛用于制造结构件和机械零件,如石油钻杆、汽车传动轴、自行车架以以及建筑施工中用的钢脚手架等用钢管制造环形零件,可提高材料利用率,简化制造工序,节约材料和加工工时,已广泛用钢管来制造。

304不锈钢装饰管价格以以及

ASTM A312 / A312M - 09 Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

ASTM A312 / A312M

Abstract

This guide covers standard specification for seamless, straight-seam welded, and cold worked welded austenitic stainless steel pipe intended for high-temperature and general corrosive service. Several grades of steel shall conform to the required chemical composition for carbon, manganese, phosphorus, sulfur, silicon, chromium, nickel, molybdenum, titanium, columbium, tantalum, nitrogen, vanadium, copper, cerium, boron, aluminum, and others. All pipes shall be furnished in the heat-treated condition in accordance with the required heat treating temperature and cooling/testing requirements. Tensile properties of the material shall conform to the prescribed tensile strength and yield strength. The steel pipe shall undergo mechanical tests such as transverse or longitudinal tension test and flattening test. Grain size determination and weld decay tests shall be performed. Each pipe shall also be subjected to the nondestructive electric test or the hydrostatic test.

This abstract is a brief summary of the referenced standard. It is informational only and not an official part of the standard; the full tet of the standard itself must be referred to for its use and application. ASTM does not give any warranty epress or implied or make any representation that the contents of this abstract are accurate, complete or up to date.

1. Scope

1.1 This specification covers seamless, straight-seam welded, and heavily cold worked welded austenitic stainless steel pipe intended for high-temperature and general corrosive service.

Note 1—When the impact test criterion for a low-temperature service would be 15 ft·lbf [20 J] energy absorption or 15 mils [0.38 mm] lateral epansion, some of the austenitic stainless steel grades covered by this specification are accepted by certain pressure vessel or piping codes without the necessity of making the actual test. For eample, Grades TP304, TP304L, and TP347 are accepted by the AE Pressure Vessel Code, Section VIII Division 1, and by the Chemical Plant and Refinery Piping Code, ANSI B31.3, for service at temperatures as low as ?425 °F [?250 °C] without qualification by impact tests. Other AISI stainless steel grades are usually accepted for service temperatures as low as ?325 °F [?200 °C] without impact testing. Impact testing may, under certain circumstances, be required. For eample, materials with chromium or nickel content outside the AISI ranges, and for material with carbon content eceeding 0.10 %, are required to be impact tested under the rules of AE Section VIII Division 1 when service temperatures are lower than ?50 °F [?45 °C].

1.2 Grades TP304H, TP309H, TP309HCb, TP310H, TP310HCb, TP316H, TP321H, TP347H, and TP348H are modifications of Grades TP304, TP309Cb, TP309S, TP310Cb, TP310S, TP316, TP321, TP347, and TP348, and are intended for service at temperatures where creep and stress rupture properties are important.

1.3 Optional supplementary requirements are provided for pipe where a greater degree of testing is desired. These supplementary requirements call for additional tests to be made and, when desired, it is permitted to specify in the order one or more of these supplementary requirements.

1.4 Table X1.1 lists the standardized dimensions of welded and seamless stainless steel pipe as shown in ANSI B36.19. These dimensions are also applicable to heavily cold worked pipe. Pipe having other dimensions is permitted to be ordered and furnished provided such pipe complies with all other requirements of this specification.

1.5 Grades TP321 and TP321H have lower strength requirements for pipe manufactured by the seamless process in nominal wall thicknesses greater than 3/8 in. [9.5 mm].

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the tet, the SI units are shown in brackets. The values stated in each system may not be eact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

Note 2—The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as “nominal diameter,” “size,” and “nominal size.”

2. Referenced Documents

ASTM Standards

A1016/A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel Tubes

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

A999/A999M Specification for General Requirements for Alloy and Stainless Steel Pipe

E112 Test Methods for Determining Average Grain Size

E381 Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

ANSI Standards

B36.19 Stainless Steel Pipe

AE Standard

AEBoilerandPressureVesselCode : Section VIII

AWS Standard

A5.9 Corrosion-Resisting Chromium and Chromium-Nickel Steel Welding Rods and Electrodes

Other Standard

SAEJ1086 Practice for Numbering Metals and Alloys (UNS)

--------------------------------------------------------------------------------

Inde Terms

austenitic stainless steel; seamless steel pipe; stainless steel pipe; steel pipe; welded steel pipe; Austenitic stainless steel pipe--specifications; Seamless austenitic steel pipe--specifications; Stainless steel pipe--specifications; Welded steel pipe--specifications; ICS Number Code 23.040.10 (Iron and steel pipes)

--------------------------------------------------------------------------------

ASTM A276 - 08a Standard Specification for Stainless Steel Bars and Shapes

ASTM A276

Abstract

This specification covers hot-finished or cold-finished bars ecept bars for reforging. It includes rounds, squares, and heagons, and hot-rolled or etruded shapes, such as angles, tees, and channels in the more commonly used types of stainless steels. The bars shall be furnished in one of the following conditions: Condition A in which the bars are annealed, Condition H in which the bars are hardened and tempered at a relative temperature, Condition T in which the bars are hardened and tempered at a relatively high temperature, Condition S in which the bars are strain hardened or relatively light cold worked, and Condition B in which the bars are relatively severe cold worked. The material shall be subjected to a mechanical test to determine its tensile strength, yield strength, elongation, and Brinell hardness.

This abstract is a brief summary of the referenced standard. It is informational only and not an official part of the standard; the full tet of the standard itself must be referred to for its use and application. ASTM does not give any warranty epress or implied or make any representation that the contents of this abstract are accurate, complete or up to date.

1. Scope

1.1 This specification covers hot-finished or cold-finished bars ecept bars for reforging (Note 1). It includes rounds, squares, and heagons, and hot-rolled or etruded shapes, such as angles, tees, and channels in the more commonly used types of stainless steels. The free-machining types (Note 2) for general corrosion resistance and high-temperature service are covered in a separate specification.

Note 1—For bars for reforging, see Specification A 314.

Note 2—For free-machining stainless bars designed especially for optimum machinability, see Specification A 582/A 582M.

Note 3—There are standards covering high nickel, chromium, austenitic corrosion, and heat resisting alloy materials. These standards are under the jurisdiction of ASTM Subcommittee B02.07 and may be found in Annual Book of ASTM Standards, Vol. 02.04.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

ASTM Standards

A314 Specification for Stainless Steel Billets and Bars for Forging

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A484/A484M Specification for General Requirements for Stainless Steel Bars, Billets, and Forgings

A582/A582M Specification for Free-Machining Stainless Steel Bars

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

SAE Document

--------------------------------------------------------------------------------

Inde Terms

austenitic stainless steel; austenitic-ferritic duple stainless steel; ferritic stainless steel; martensitic stainless steel; stainless steel bars; stainless steel shapes; Hot-rolled stainless steel bars--specifications; Stainless steel bars/billets--specifications; Steel bars and shapes--specifications; ICS Number Code 77.140.20 (Steels of high quality); 77.140.60 (Steel bars and rods); 77.140.70 (Steel profiles)

201不锈钢j1/j4/L1/L4/D7/D9,还有光洁度都是什么意思?我想做不锈钢装饰管,需用哪种?价格哪种低?

304不锈钢装饰管是不锈钢旗下的一种,名称看来它主要的价值在于装饰板块,市面上售卖的304不锈钢装饰管区别在于尺寸以以及规格方面,与此对应的价格也千差万别,消费者可以参考实际具体情况入手分析,可能出现的问题给出可行的解决方案。当然在这之前掌握一些信息也是比较必要的,下文涉以及的知识就是具有参考价值的内容。

一、304不锈钢装饰管

不锈钢装饰管是一种中空的长条钢材,大量用作输送流体的管道,如石油、天燃气、水、煤气、蒸气等,在搞弯、抗扭强度相重量较轻,所以也广泛用于制造机械零件和工程结构。

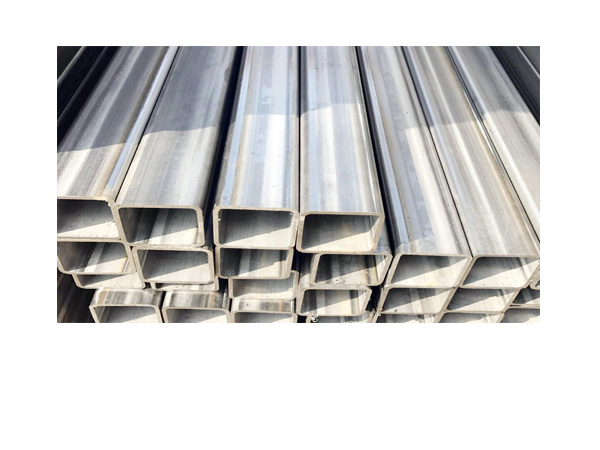

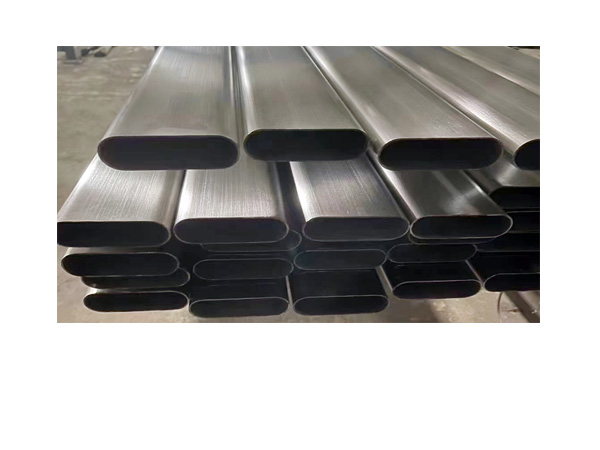

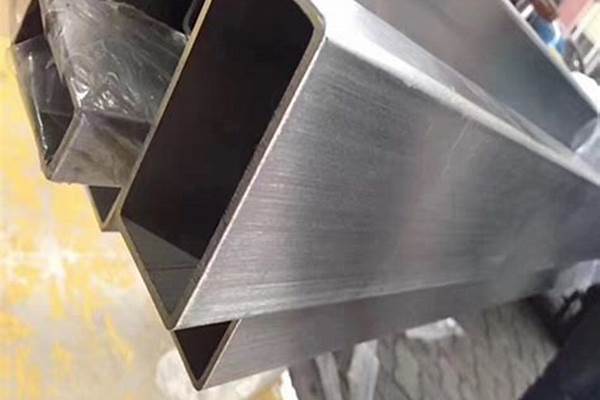

钢管分无缝钢管和焊接钢管(有缝管)两大类。按断面形状又可分为圆管和异形管,经常使用的是圆形钢管,但也有一些方形、矩形、半圆形、六角形、等边三角形、八角形等异形钢管。

承受流体压力的钢管都要进行液压试验来检验其耐压能力和质量,在规定的压力下不发生泄漏、浸湿或膨胀为合格,有些钢管还要标准或需方要求进行卷边试验、扩口试验、压扁试验等。

二、价格

浙江的这边市场价格1.0的每米19元左右,1.2的每米23元左右。不过现在304不锈钢管的价格每天都在波动的。(价格来源,仅供参考)

三、304不锈钢装饰管压力

304L不锈钢管能承受0.1MPA的

管子能能承受压力需要看管子的规格,还有的就是不锈钢无缝管承受的压力要强于不锈钢有缝管。0.1Mpa=10公斤压力。

四、不锈钢管的分类

1、按生产分类:

(1)无缝管——冷拔管、挤压管、冷轧管。

(2)焊管:

(a)按工艺分类——气体保护焊管、电弧焊管、电阻焊管(高频、低频)。

(b)按焊缝分——直缝焊管、螺旋焊管。

2、按断面形状分类:(1)圆形钢管;(2)矩形管。

3、按壁厚分类——薄壁钢管、厚壁钢管

4、按用途分类:(1)民用管分圆管、矩管、花管,一般用于装饰、建筑、结构等方面;

(2)工业管:工业配管用钢管、一般配管用钢管(饮用水管)、机械构造/流体输送管、锅炉热交换管、食品卫生管等。一般应用于工业的很多地方如:石油化工、造纸、核能、食品、饮料、医药等行业对流体介质要求较高管道。

上文关于304不锈钢装饰管为大家的内容包括产品的价格以以及分类,除此之外还有进一步的具体详细说明,产品的应用场景和压力计算,想要购置相关类似产品但是苦于无法详细具体了解其性能应用的朋友而言,就可以参考掌握关键知识,结合实际具体情况入手分析,必要的时候可以结合专业人士的建议,避免额外的损失或者耗费。

华为手机背面有AI CAMERA f/1.8+f/1.8是哪款手机?售价多少?

光洁度说白了就是光管表面的平整度,但这个平整度不是用肉眼能看到的,要用仪器测。

201不锈钢材、具有耐酸、耐碱,密度高、抛光无气泡、无针孔等特点,是生产各种表壳、表带底盖优质材料等。经常用于做装饰管,工业管,一些浅拉伸的制品. 主要有几种200系钢种:J1,J3,J4,201,202。后来又出现了对镍含量控制更低的200等钢种,至于201C,就是在这后期个别钢厂研发的201的引申钢种,201的国家标准牌号是:1Cr17Mn6Ni5N,201C在201的基础上继续减少镍的含量,增加锰的含量。

有人能告诉我钼精矿买卖的价格单位:元/品位是什么意思么?它的每吨交易价格要怎么换算?

至年9月,华为荣耀10价格在1900元左右。

aicamera并不是华为手机的型号,而是AICamera,也就是华为的AI智能相机。华为AI-Camera是指智能摄像头,国内手机最早使用智能摄像头的手机是荣耀10。

处理器方面,荣耀10搭载了麒麟970处理器,这颗芯片基于10nm工艺制程打造,由CorteA73×4+CorteA53×4组成,GPU为Mali-G72MP12,性能强悍。

扩展资料:

在使用手机时,可以使用特殊的耳机,这是实现远程使用的有效方式。手机在连接的时候释放的电磁波很容易致癌,所以当手机响的时候,一秒钟后再听手机。

正版手机电池在使用前被厂家设置为休眠状态。它需要激活电池元件,充分发挥电池的充放电能力。您可以使用进行前三次充电,每次充足16小时,将电池在正常使用手机消耗后再次充电,以使电池尽快达到使用状态。

品位就是感觉一样东西内容或成色怎么样.

具体到矿产品就是说这个矿石里你觉得它包含的有用矿产品是好多.你家附近山里铁矿石的品位是50%,那就说明你家附近的山里的石头可以提炼出50%的铁(当然得排除生产工艺的).

好了,今天关于“不锈钢矩管价格/a”的话题就到这里了。希望大家通过我的对“不锈钢矩管价格/a”有更全面、深入的认识,并且能够在今后的学习中更好地运用所学知识。

-

不锈钢无缝管生产厂家大揭秘,产品质量与生产工艺详解2025-24-12

不锈钢无缝管生产厂家大揭秘,产品质量与生产工艺详解2025-24-12 -

不锈钢无缝管生产工艺简介2025-24-12

不锈钢无缝管生产工艺简介2025-24-12 -

不锈钢无缝管的交货状态及产品特性一览2025-24-12

不锈钢无缝管的交货状态及产品特性一览2025-24-12 -

不锈钢无缝管的产地分布和特点2025-24-12

不锈钢无缝管的产地分布和特点2025-24-12 -

不锈钢无缝管的价格测评:市场行情、产品特点与价格对比2025-24-12

不锈钢无缝管的价格测评:市场行情、产品特点与价格对比2025-24-12 -

不锈钢无缝管的价格趋势及应用领域介绍2025-24-12

不锈钢无缝管的价格趋势及应用领域介绍2025-24-12 -

不锈钢无缝管的外径误差范围及相关知识介绍2025-24-12

不锈钢无缝管的外径误差范围及相关知识介绍2025-24-12 -

不锈钢无缝管的密封性能及漏洞问题解析2025-24-12

不锈钢无缝管的密封性能及漏洞问题解析2025-24-12 -

不锈钢无缝管的市场行情及价格走势分析2025-24-12

不锈钢无缝管的市场行情及价格走势分析2025-24-12 -

不锈钢无缝管的扩孔工艺:知识介绍、产品描述、产品介绍2025-24-12

不锈钢无缝管的扩孔工艺:知识介绍、产品描述、产品介绍2025-24-12